The frequency of rotation of DC motors can be modified in three ways: a change in the resistance of the rja chain anchors, magnetic flux change f change in input voltage to the motor U.

The frequency of rotation of DC motors can be modified in three ways: a change in the resistance of the rja chain anchors, magnetic flux change f change in input voltage to the motor U.

The first way to apply seldom because it is uneconomical, gives you the ability to maintain speed control only under load and use mechanical characteristics, with different slope. When the regulation on the method of maximum power point remains constant. Magnetic flux is not changed, and if approximately assume that current, defined by the long-term permissible temperature rise of the motor is the same at all speeds, the time limit must also be the same at all speeds.

Speed control of DC motors with parallel excitation magnetic flux change got significant circulation. The amount of flow you can change a dimmer function. When you increase the resistance of the rheostat decreases the strength of the excitation current and magnetic flux and speed increases. Each minus the value of the magnetic flux f correspond to increased value n0 and (b).

Thus, when the magnetic flux weakening mechanical characteristics constitute a straight line above the natural characteristics, non-parallel to it and having the higher slope than smaller streams they correspond to. Their number depends on the number of contacts at reostate and can be quite large. Thus, the weakening of the flow speed control can be made almost infinitely variable.

If still tentative take maximum permissible amperage at all speeds equal, then P = const

Thus, when regulating the frequency of rotation of magnetic flux change maximum engine power remains constant at all speeds. Maximum permissible moment varies inversely proportional to speed. When increasing the engine speed increases field weakening sparks under the brushes due to reactive growth e. d. c food in dial-up sections of the engine.

When the engine is running with impaired flow decreases resistance, particularly when the load on the engine shaft is variable. Low flow value markedly razmagnichivajushhee action reaction anchors. Because razmagnichivajushhee action is determined by the force of the motor armature current when the load changes, engine speed changes dramatically. To improve the stability of regulated engines with parallel excitation typically provide weak coherent excitation winding stream that partly offsets the effect of armature reaction razmagnichivajushhee.

Engines that are designed to work with high speeds, must have high mechanical strength. At high speeds the engine vibration and noise are increasing. These reasons limit the highest motor speed. The lowest rotational speed also has a practical limit.

Nominal moment determines the size and cost of DC motors (as well as asynchronous motors). In the least, in this case the nominal engine speed, some power nominal torque of its increase. Dimensions of the engine with this increase.

In industry the most often used engines with ranges of regulation

To extend the range of regulation of rotation speed of magnetic flux change sometimes special motor excitation scheme that allows you to improve the switching and reduce the impact of reaction anchors at high engine speeds. Powered coils of two pairs of Poles share, forming two independent circuits: a chain coils one pair of Poles and a chain of other couples.

One of the chains include the DC voltage, in another change the magnitude and direction of the current. With this inclusion of total magnetic flux that interacts with an anchor, you can change from the sum largest values threads coils two chains to their difference.

Coil incorporated so that one pair of poles is always full of magnetic flux. Therefore, the reaction of anchors has affected to a lesser degree than when the magnetic flux weakening of all Poles. So you can adjust all the Multipole DC motors with wave winding armature. When this is achieved the sustained operation of the engine in a large range of speeds.

Speed control of DC motors by changing input voltage requires the application of special schemes.

DC motors compared with asynchronous considerably heavier and more expensive. K. p. d. these engines below and their operation is more complicated.

Industrial enterprises receive energy for three-phase current, for the purpose of obtaining special DC converters. This is due to the incremental loss of energy. The main reason of application for metal-cutting machine tools drive DC motors with parallel excitation is the ability to practically and cost-effectively managing their variable rotational speed.

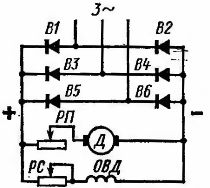

The Soviets used complete drives with rectifiers and DC motor with parallel excitation (fig. 1). Through a rheostat PC change the amperage of the motor excitation, providing almost infinitely variable control its rotational speed in the range 2:1. Drive Kit includes the starting rheostat REGISTER of ENTERPRISES, as well as protection, in Figure 1. 1 not shown.

Figure. 1. scheme of DC electric with rectifier

Выпрямители (B1 – В6), погруженные в трансформаторное масло, и всю аппаратуру помещают в шкафу управления, а реостат PC устанавливают в месте, удобном для обслуживания.