Currently, such chemical current sources, as lithium batteries (CRA) and the galvanic elements, are widely used as in portable electronics: Tablet PC, cellphones, laptops, MP3 players, etc., and in the energy, electron transport and energy systems.

Companies struggling to make storage density increase seek energy in their products in order to increase the battery life for devices. HA rakteristikam modern lithium batteries is higher than that of batteries made by other technologists Yam, for example, Ni-MH (nickel-metal hydride battery market) and NiCad (nickel-cadmium batteries).

Lithium batteries have the following advantages for achieving:

- high specific capacity.

- small weight;

- There is no "memory effect", which gives you the ability to charge and recharge as necessary as

- низкий уровень саморазряда – не более 3…5% в месяц. Однако литиевые аккумуляторы имеют и ряд недостатков, а именно:

- higher cost compared to Ni-Cd batteries;

- the need for a protection scheme which limited provides the maximum voltage at each end of the battery during its charge and protects the ELE ment from lowering too low voltage at discharge.

- the need for another protection circuits that paradise controls temperature element and restricts the maximum currents of his charge and discharge.

The main characteristics of lithium battery, to some extent, depend on the chemical composition of their components and DoD may vary within the following limits:

- specific power capacity (c) 110. 243 w·h/kg,

- the voltage of a single element:

- номинальное 3,6…3,7 В;

- maximum 4.2;

- minimum 2, ... 3.0;

- load current relative to the capacity provided in

- постоянный до 3…5С (тип.);

- optimum up to 1 c;

- саморазряд при комнатной температуре 3…5% в месяц;

- the number of charge/discharge cycles "to reduce 80% up to 600;

- operating temperature range -20 ... 60° c (optimum 20° c).

Development of production technology for lithium batteries

The main tasks are technology development re decision problems ensure safe operation and reduced and the high cost of batteries development in these 2 areas has led to the development of lithium polymer (Li-pol) batteries.

The major difference from the now familiar Li-ion, lies in the type of electrolyte used in them.

When designing a Li-pol batteries made of solid polymer electrolyte Hoy Su. It is similar to plastic kovuju plastic and does not conduct electrical current, but enable Exchange em ions. Such polymer replaced traditionally IP polzuemyj in porous separator soaked Elek trolitom. Polymer electrolyte simplifies the process of production, characterized by more security and enable ing to produce thin batteries. An additional advantage of such technology production AK kumuljatorov is that the absence of liquid jelektroli Ta eliminates the possibility of ignition. The final column element is about 1 mm that enables you to develop botchikam to freely choose its shape, dimensions and ocherta, and even include it in fragments of clothing.

Dignity of lithium-polymer batteries:

- slight decrease in voltage as time series;

- small self-discharge;

- freedom to choose the form of the CRA;

- thickness of elements from 1 mm;

- increased safety.

However, compared with liquid electrolytes in lithium-ion batteries, polymer electrolytes have greater thermal Ionic conductivity, moreover, it decreases at temperatures below zero.

Thus, developers of the Li-pol battery has two tasks: broadening the range of working temperatures, however, and the search for the most suitable electrolyte with increasing conductivity remained and, moreover, compatible with the trodnymi electronic materials.

Li-pol batteries produce many world producers producing, but manufacturing technology Li-pol battery and electrode materials that are used for this and re ceptura electrolyte from different companies vary widely.

As a result, the CRA from different manufacturers have different HA rakteristiki and different dimensions at the same it bone. CRA production technology, namely the ratio of electrolyte and temperature of its polymerization exert a strong influence on the homogeneity of the polymer to the Torah influenced the stability of the Li-pol battery.

It should be noted that the product line companies about the diff includes primary (non-rechargeable) and secondary (rechargeable) lithium batteries.

Frost tolerant Li–Pol AKB

The main disadvantage of lithium AK kumuljatorov is a significant reduction in their capacity and fast time series at low temperatures. The CRA have pain most manufacturers minimum RA bochaja temperature is -20° c.

The company EEMV has developed and serially producing dit lithium-polymer CRA working in tempera ture -400С и выше (табл.1). При температуре -40°С и токе разряда 0.2С (напряжение отсечки 2.75 В) емкость АКБ остается на уровне 70% от номинальной, что превышает требование военных стандартов – 40%.

Table 1

|

The name of the |

Rated voltage, v |

Capacity. mAh |

Dimensions, mm |

Weight, g |

|||

| LP383454LC | 3.7 | 720 | 670 | 3.8 | 34 | 54 | 14,4 |

| LP603048LC | 3.7 | 900 | 850 | 6 1 | 30 | 48 | 18 |

| LP963450LC | 3.7 | 1800 | 1700 | 9.6 | 34 | 50 | 36 |

| LP103450LC | 3.7 | 1850 | 1800 | 10 | 34 | 50 | 37 |

| LP505597LC | 3.7 | 3100 | 2900 | 5 | 55 | 97 | 62 |

Frostproof CRA series from the company EEMV Mar dangerous files is blocked characters at the end of the LC appellation, for example, LP103454LC has the capacity of 2 AH (see photo at the beginning of the article), where:

- LP – тип аккумулятора (Li-Pol);

- 10 – толщина аккумулятора (1,0 мм);

- 34 – ширина аккумулятора (34 мм);

- 54 – длина аккумулятора (54 мм);

- LC – низкотемпературная версия.

Thanks to the launch of the production of this series akku muljatorov opens new possibilities of application of Li-pol battery.

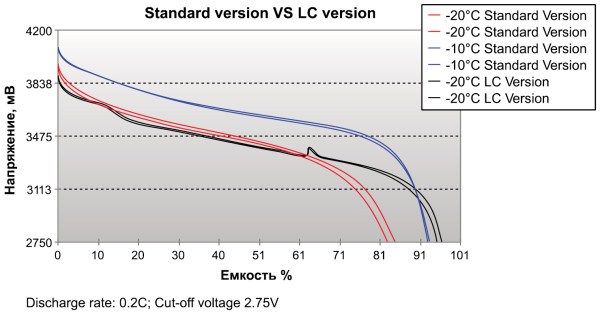

Based on capacity and tension at the rate information -10° c and -20° c for the standard version (1 and 2 curves), as well as for low-temperature LC-battery version (curve 3) are shown in Fig. 1. These curves were filmed at bit current 0.2 c to otsech voltage Ki 2.75 in table 2 shows the absolute values of the capacity of the CRA under the same conditions a number of times.

Как видно из рис.1 и табл.2. стандартные АКБ компании ЕЕМВ, допускают возможность разряда только до температуры -20°С, и при этом, у них потеря емкости составляет 15…17%. Это немного, но их минимально допустимая температура -20°С недостаточная для холодных районов Земли.

Table 2

|

Version battery/temperature |

Battery energy intensity at different operating temperatures,% |

|||

| 60° c | 25° c | -20° c | -40° c | |

| Standard battery | 98 | 98 | 83 | – |

| Низкотемпературная (LC) | 98 | 98 | 90 | 70 |

У морозоустойчивой LC-ceрии аккумуляторов также происходит снижение емкости при отрицательной температуре. Это снижение составляет 25…30%, при температуре -40°С, что является весьма неплохим показателем. Учитывая, что стоимость Вт·ч новой серии АКБ выше стандартной версии примерно на 18…25%. можно утверждать, что ЕЕМВ имеет линейку очень перспективных аккумуляторов для применения в суровом арктическом или высокогорном климате. Особенностью морозоустойчивой LC-серии аккумуляторов от компании ЕЕМВ является то, что они могут не только отдавать заряд при отрицательной температуре, но и их можно заряжать при низкой температуре. АКБ серии LC можно заряжать при температуре выше -10°С током 0,2С, но при этом АКБ можно зарядить только до 70% от номинальной емкости (в технических данных большинства производителей. эта информация, как правило, отсутствует).

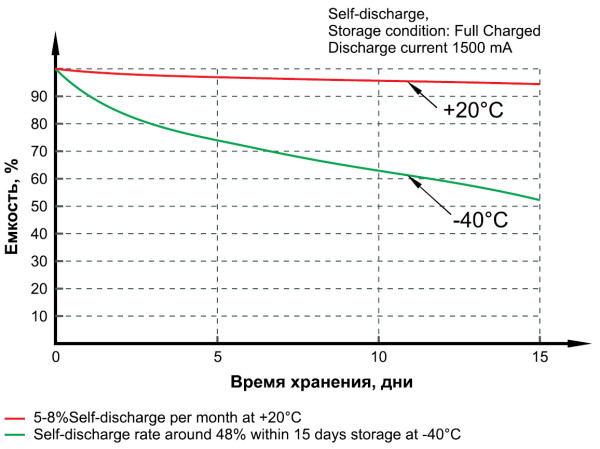

An important parameter of frost-resistant battery is to change their properties at low temperature storage. In Fig. 2 shows the dependence of capacitance on temperature storage at 20° c and -40° c. Batteries time rjazhalis shock 1500 Ma after storage for 15 Su talk (at a temperature of -40° c) and 30 days (at a temperature of 20° c). During this time, the capacity of the battery, stored at the rate information 20 0С. уменьшилась на 7%, а хранившегося при температуре -40°С – на 48%.

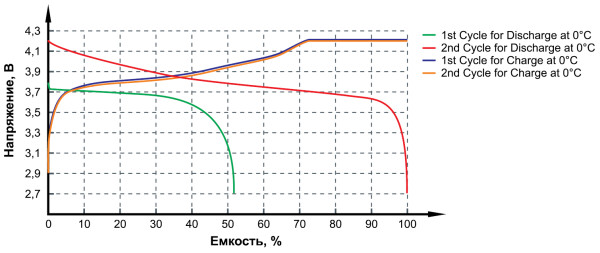

Subsequently, the battery, which was kept 15 days at temperature -40° c, however, and was then fully discharged, was charged at a temperature of 0° c, and was again tested its capacity (fig. 3). In Fig. 3 marked:

- – первый цикл разряда при 00With;

- – второй цикл разряда при 00With;

- – первый цикл заряда при 00With;

- – второй цикл заряда при 00With.

Измеренная в ходе второго цикла разряда емкость АКБ составила 99% от первоначального значения. Это очень хорошие результаты, ведь температура -40°С для аккумулятора – это очень суровые условия. Тот факт, что за 15 дней хранения при такой температуре АКБ сохранила половину своей емкости, а при последующем заряде емкость АКБ практически полностью восстановилась, говорит о высоком качестве морозоустойчивой LC-серии аккумуляторов ЕЕМВ.

Conclusion

In some cases, quite relevant to operate at low temperatures, for example, means radiosvja Zi, portable equipment, devices, individual CIG marginalization (electronic beacon rescuer), test and control and diagnostic equipment, etc. in this case, it is advisable to use the CRA LC series discussed above company EEMV. Not all prod drivers lithium-polymer CRA have its line of Pro products are frost-resistant battery.

The main advantage of modern lithium-polymer battery is ERS lack liquid Elek trolita, making them safer than having a slightly better specific characteristics, but fire hazardous lithium-ion batteries. In the course of conducting inspections on safety in the use of Pro:

- short circuit

- perezarjad;

- forced discharge.

- crushing;

- breaking Li-pol batteries showed significantly higher levels of security compared with the NIJ Li-ion batteries with liquid electrical trolitom.

In this regard, is not in doubt the prospects for serious expansion of the Li-pol battery and use them in a wide variety of technical areas. So much so that the appearance of elements Li-pol JSCB thickness 1 mm only Noe opened, before designers electron devices, new opportunities for the ultimate size and shape of the new equipment and removed many OGRE reduction relative to mikrominiatjurizacii radiojelektron devices.

Author: Andrew Dougan, Belgorod