Предлагаемое устройство позволяет перейти от релейного принципа управления вентилятором системы охлаждения двигателя “температура выше нормы — включён, ниже нормы - выключен” к более, по мнению автора, благоприятному для двигателя пропорциональному управлению. Теперь с ростом температуры охлаждающей жидкости частота вращения ротора вентилятора линейно увеличивается.

Today, in many automotive engines the cooling fan is electrically operated, but control it in most cases on the relay principle. Such control has only one advantage — the ease of implementation. Enough to have a temperature sensor with a contact output, directly or via intermediate relay controlling the fan motor.

Основной недостаток этого метода — резкое снижение температуры охлаждающей жидкости на выходе радиатора после включения вентилятора. Работающий на полную мощность вентилятор понижает температуру охлаждающей жидкости на выходе радиатора на 15…25°С и более. Поступая в рубашку охлаждения двигателя, существенно охлаждённая жидкость наносит термоудар по горячим поверхностям, что негативно сказывается на работе двигателя. Для его комфортной работы температуру охлаждающей жидкости желательно поддерживать близкой к оптимальной, рекомендуемой заводом-изготовителем, а резкие скачки температуры (термоудары) должны быть исключены в принципе.

For vehicles with mechanical cooling fan motor, this is achieved by connecting the fan to the crankshaft of the engine through a viscous coupling. It changes transmitted to the fan shaft torque depending on engine coolant temperature. This stabilizes the temperature.

The proposed device is an electronic analogue of the viscous coupling for fan with electric drive. It automatically regulates frequency of rotation depending on the coolant temperature.

Устройство работает от бортсети автомобиля при напряжении в ней 10… 18 В и может управлять вентилятором с максимальным потребляемым током до 20 А или до 30 А при условии увеличения площади теплоотвода силовых элементов. Собственное потребление тока устройством не превышает нескольких миллиампер. Значения температуры включения вентилятора с минимальной частотой вращения и температуры, при которой частота вращения вентилятора достигает максимума, задают с дискретностью 0,1 °С при программировании микроконтроллера.

When sensor failure coolant temperature, the device switches to emergency mode which is safe for the engine to drive to the repair shop.

Diagram of the device depicted in Fig. 1. Measures the temperature of the digital sensor DS181B20 (BK1). The application of this sensor eliminates the calibration of manufactured devices and improves repeatability.

Information about the temperature sensor reads from the microcontroller ATtiny2313A-PU (DD1), which is clocked by pulses with frequency of 1 MHz from internal RC oscillator. Proportional to temperature it regulates the voltage to the fan motor and thus the frequency of rotation of the rotor. The engine is fed pulse voltage, the DC component which determines the frequency of rotation depends on the fill factor (the ratio of pulse duration to the period of their recurrence). The fill factor defines the eight-bit binary numbers loaded into the comparison register operating in the PWM mode timer of the microcontroller.

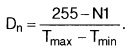

Generated by the microcontroller pulses control the operation of the power key on the field VT1 transistor, connecting and disconnecting a power circuit of the fan motor from the onboard network of the car. In this the constant component is applied to the motor voltage is equal to![]()

where are U0 — voltage of battery, V; N is the number loaded in the register of the microcontroller. It can be changed in increments of

When the voltage of battery 12 V ΔU=0,05, which allows you to adjust the fan speed almost seamlessly.

To ensure the reliability of key transistor VT1 in the transient modes the microcontroller driving it through the driver ТС4420ЕРА (DA1). Modern field effect transistors having a very low open channel resistance (a few milliohms), capable of switching significant current even without the application of heat. However, the large input capacitance of the MOSFET, reaching from high-power devices up to several thousands of picofarads, in the process of switching charges and discharges. It takes more time, the more the output impedance of the source control signal.

The bad thing is that in the process of charge of the capacitance field effect transistor is in active mode and resistance of its channel is rather large. Therefore, the switching time in the crystal, transistor stands out with considerable power, which can lead to overheating and permanent damage. The only way to deal with this phenomenon is the acceleration of the recharging process. For this FET is controlled through specialized amplifiers (drivers) that have low output impedance and provides a high (up to several amps) pulse charge-discharge current. This allows for quick recharging of the input capacitance of the MOSFET and, therefore, minimizes the duration of its operation in the active mode and reduces power dissipation on the power.

Resistor R4 supports on driver input logic low voltage during startup of the microcontroller until all outputs remain in high impedance state. This eliminates unnecessary at this time, the opening of the transistor VT1. Diode VD1 eliminates the pulses of self-induced EMF arising in the windings of the fan motor in the moments closing of the transistor VT1.

During the program of the microcontroller constantly monitors the availability and operability of the temperature sensor. If no connection with it, it goes into emergency mode. In this mode, regardless of coolant temperature the fan 33 will be turned up to full power, and then at the same time off. Of course, this is not optimal cooling of the engine, but it prevents complete failure in the absence of cooling. About transition to emergency mode is indicated by the activation of the led HL1. If the loss of communication with sensor was temporary, after its restoration the device switches to normal operation mode.

The program of the microcontroller to control the fan incorporated in the form of constants the following source data:

- Tmin = 87 — coolant temperature, °C, at which the fan should begin to operate with a minimum frequency of rotation;

- TP = 92 — coolant temperature, °C, at which the fan speed must reach a maximum value;

- N1 = 70, the value loaded into the compare register of the timer code so that a rotation of the rotor fan with the minimum frequency.

As you know, industrial sensors designed to control the operation of the cooling fans have two main parameters — the temperature on and temperature off. They should be selected as TP and Tmin. The value of N1 need to ask the way in which the DC component of the voltage at the fan motor is equal to the voltage pick-up UTr.

Проблема в том, что напряжение трогания не принято указывать в технических данных вентиляторов, поэтому найти в литературе или в документации значение этого параметра автору не удалось. Его пришлось определять экспериментально. Методика проста — подавая напряжение на двигатель, найти его значение, при котором вал начнёт медленно (оборот за одну-две секунды), но устойчиво вращаться. Для большинства двигателей постоянного тока с номинальным напряжением питания 12 В напряжение трогания лежит в пределах 3…5 В.

When you run the program the microcontroller on the basis of the values TPTmin and N1 counts Dn — desired steepness according to values loaded register compare timer code temperature:

Then begins the main loop of the program. First of all, there is a check connection with the temperature sensor, and in its absence — the transition to emergency operation mode. Such a test program executes every second. If the next test shows that the sensor works, restored normal operation.

When the sensor is OK, it measures the current coolant temperature T. If it is lower Tmin the program turns off the fan, otherwise, calculates the desired value of the control code according to the formula![]()

Proportionally he will set the fill factor supplied voltage and therefore the frequency of rotation of the rotor. As a result, the temperature of the coolant at a constant engine load is kept constant. At variable load temperature varies in a small range within the interval Tmin…ТP.

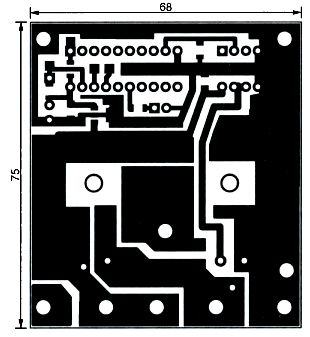

Все детали устройства, за исключением датчика ВК1 и светодиода HL1, размещены на печатной плате размерами 58×65 мм, чертёж которой показан на Figure. 2, and the location element Fig. 3.

The chip is soldered directly to the Board without panels, the use of which in conditions of high vibration is undesirable. The Board has not shown in the diagram, pads SCK, RST, VCC, MISO, MOSI, GND, which at the time of programming the microcontroller soldered the same wires from the programmer. This fee and the programmer during programming should have a voltage of +5 V (VCC) from a single source.

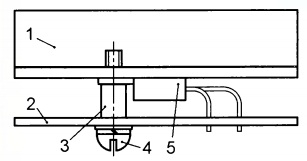

The fee is designed to fit the resistors and capacitors of size 1206 SMD. Diode SR2040 (URL: http://files.rct.ru/pdf/diode/5261755198365.pdf (27.06.16)) — dvuhfasadnye housing Т0220АС. Together with the transistor IRF3808 it fixed with the application of heat conducting paste on a common heat sink with an area of cooling surface of about 60 cm2.

The principle of attachment 5 of the transistor or diode to the heat sink 1 and the entire Assembly to the circuit Board 2 shown in Fig. 4. The diode is isolated from the heat sink mica gasket, and attaching screw 4 and the metal sleeve 3 insulation sleeve (sealing elements not shown). Between the body diode and transistor is a third point of attachment of the heat sink to the Board. Here it is also fastened with screws and grommet.

Все печатные проводники платы, по которым течёт ток двигателя вентилятора, должны быть покрыты слоем припоя толщиной не менее 0,7… 1 мм, а сечение подводящих проводов должно обеспечивать пропускание этого тока.

Led HL1, it is advisable to take the vehicle to the driver had information about the current mode of operation of the device.

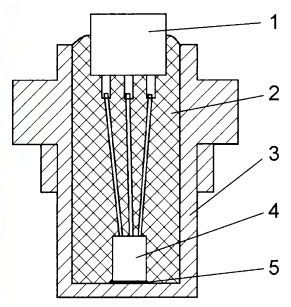

Датчик DS18B20 (ВК1) следует поместить в корпус от штатного контактного датчика температуры охлаждающей жидкости, из которого предварительно следует удалить всю “начинку”. Такой корпус можно и выточить из латуни с сохранением габаритных и присоединительных размеров. Размещение датчика DS18B20 в корпусе показано на Figure. 5. The sensor 4 is soldered to its findings connector 1 is placed in the cavity of the housing 3 so that its tip coated with a layer of heat conducting paste 5, touch the bottom of the cavity. Then the cavity is filled with heat-resistant sealant 2.

Connector 1 should be protected against corrosion of contacts to be splash-proof, securely locking counterpart, preventing its undocking under the action of vibration. The prepared sensor installs in place of the regular.

The assembled Board is placed in a housing of appropriate size, which is placed in the engine compartment of the vehicle. The casing has ventilation holes.

The ATtiny2313A microcontroller can be replaced by another AVR family that has at least one 8-bit and one 16-bit timer and at least 2 Kbytes of program memory. Of course, the replacement of the microcontroller will require recompilation of the program and possible changes to the topology of the PCB.

Is driver noninverting low-side ТС4420ЕРА you can use another kind, for example, МАХ4420ЕРА.

The diode with the Schottky barrier SR2040 can be replaced the same with a permissible reverse voltage of at least 25 In and allowed a direct current of at least the operating current of the fan. However, the Schottky diodes with a reverse voltage of more than 40 In is not recommended, since a larger forward voltage drop at this diode will lead to an increase in heat dissipation.

Замену полевому транзистору IRF3808 с изолированным затвором и каналом n-типа следует подбирать с допустимым постоянным током стока при температуре 100 °С в 2,5…3 раза больше рабочего тока вентилятора и с сопротивлением открытого канала при рабочем токе вентилятора до 20 А — не более 10 мОм, а 20…30 А — не более 7 мОм. Допустимое напряжение сток- исток должно быть не менее 25 В, а затвор—исток — не менее 20 В.

Correctly assembled from serviceable details, the device will require the establishment only in the case when the inputs in the attached version of the program, mentioned earlier, is not adequate. In this case they need to adjust in the program source code, recompile it in the IDE Bascom AVR and upload to the memory of the microcontroller is attached to the article file Cooler-test.hex the resulting HEX file.

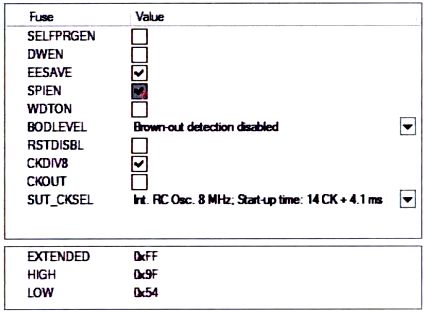

If pick-up voltage of the fan motor is unknown, it can be determined experimentally. To do this, in the memory of the microcontroller instead of a working program you need to download designed me debug the program. In the attached article file Cooler-test.it contains hex codes. The configuration of the microcontroller programming is the same for the working and test programs in accordance with Fig. 6, where an example configuration of programmer AVRISP mkll.

After 3 s after power-on program Cooler-test begins to control the fan, gradually increasing from 55 to 95 in steps of 5 units code that specifies the fill factor of the supply fan pulse voltage. This roughly corresponds to the change of the DC component of this voltage from three to five volts. The duration of each stage — 10 s, during which the fan and HL1 led is enabled, and a pause of 5 s, during which the voltage of the fan is removed, and the led is extinguished. The end of the work programme indicates a series of five short flashes of the led.

Watching the led, it is easy to determine at what stage the fan started to spin, and to determine the value of N1, which should be written in the main program.

The operation of the device in emergency mode check, disconnect connector from temperature sensor. The fan should turn on and operate at full capacity in an intermittent mode (33 — work, 33 seconds — pause). HL1 led should light up. It the desired brightness set by selection of resistor R3.

The program of the microcontroller

Author: A. SAVCHENKO, village of Zelenograd, Moscow region.

Source: Radio No. 11, 2016

Interestingly,while it is possible for this scheme to add two more output units to control two independent fans ?

А нельзя ли плату в формате layaut прикрепить к теме