При замене трамблера, или ремонта связанное с воспламенением смеси, будь то смена карбюратора, сталкиваемся с тем что нужно настроить угол опережения зажигания.

При замене трамблера, или ремонта связанное с воспламенением смеси, будь то смена карбюратора, сталкиваемся с тем что нужно настроить угол опережения зажигания.Что такое угол опережения зажигания(УОЗ)-угол поворота кривошипа от момента, при котором на свечу зажигания начинает подаваться напряжение для пробоя искрового промежутка до занятия поршнем ВМТ.

Для настройки УОЗ, большинство мастеров использует так называемый автомобильный стробоскоп, который вспыхивает в момент когда пробегает искра на свече зажигания. Подробно как пользоваться стробоскопом для настройки уоз можно увидеть в интернете. В этой же статье приведена простая схема автомобильного стробоскопа, который своими руками может собрать почти любой начинающий радиолюбитель.

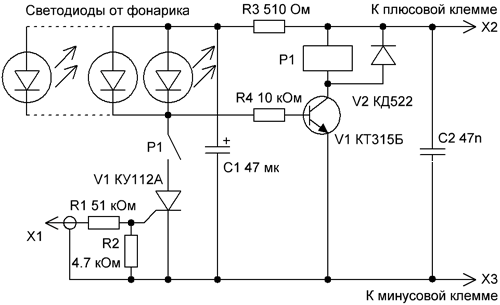

Diagram of the device:

При подключении устройства к аккумуляторной батарее конденсатор C1 через резистор R3 быстро начинает заряжаться. Достигнув определённого уровня, напряжение через светодиоды и резистор R4 поступает на базу транзистора, который открывается. При этом срабатывает реле Р1, его контакт замыкается и подготавливает цепь, состоящую из тиристора, контакта реле Р1, светодиодов и конденсатора С1 в готовность. При поступлении на управляющий электрод тиристора через делитель R1, R2 импульса с контакта Х1 происходит мгновенное открытие тиристора и конденсатор быстро разряжается через светодиоды. Происходит яркая вспышка! База транзистора, через резистор R4 и тиристор соединяется с общим проводом и транзистор закрывается, отключая реле.

Так как якорь реле имеет небольшую инерционность и остаточную намагниченность, то контакт размыкается не сразу, а через несколько мкс, увеличивая тем самым время горения светодиодов. Контакт размыкается, обесточивается тиристор и схема переходит в первоначальное состояния, ожидая следующий импульс. Благодаря этому мерцание стробоскопа становится более ярким и метка на маховике хорошо просматривается, оставляя после себя небольшой шлейф. Подбором конденсатора можно регулировать длительность горения светодиодов. Чем больше ёмкость, тем ярче вспышка, но зато длиннее шлейф метки. При меньшей ёмкости резкость метки увеличивается, но падает яркость. Делать это нецелесообразно так как настройку ОУЗ придётся делать в темноте, что не совсем удобно. После сборки стробоскопа необходимо проверить его работоспособность. Подключаем к выводам Х2 и Х3 источник постоянного напряжения 12в. При замыкании выводов Х1 и Х2 между собой должно “жужжать” реле (звонковый режим).

После сборки стробоскопа необходимо проверить его работоспособность. Подключаем к выводам Х2 и Х3 источник постоянного напряжения 12в. При замыкании выводов Х1 и Х2 между собой должно “жужжать” реле (звонковый режим).

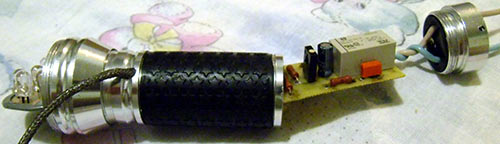

При настройке ОУЗ следует на метку маховика или шкива с помощью штриха нанести белую точку для лучшей видимости. Элементы стробоскопа размещают в корпусе светодиодного фонарика. Через задние отверстия фонарика пропускают питающие провода длиной примерно 0,5 м, на концы которых припаивают крокодильчики с соответствующей цветной маркировкой. С боку в корпусе просверливают отверстие, через которое пропускают экранированный провод контакта Х1. Длина его должна быть не более 0,5 м. На конце экранную оплётку заматывают изолентой, а к центральной жиле припаивают медный провод длиной 10 см, который служит датчиком стробоскопа. Этот провод при подключении следует намотать на высоковольтный провод первого цилиндра поверх изоляции, достаточно 3-4 витка. Намотку нужно делать как можно ближе к свече, чтобы исключить влияние соседних проводов.

О деталях: В конструкции используются малогабаритные компоненты. Транзистор КТ315 – его можно найти в любой аппаратуре прошлых лет с любым буквенным индексом. Тиристор КУ112А – от импульсного блока питания старого телевизора. Резисторы малогабаритные 0,125вт. Фонарик с диодами 6-12 штук. Если фонарик снабжен электронным маячком, то эта плата удаляется. Конденсатор C1 на напряжение не менее 16в. Диод V2 практически любой низкочастотный КД105, Д9. Реле малогабаритное (BS-115-12A-DC12V), (RWH-SH-112D, 12A, кат.=12в). Можно так же использовать отечественные малогабаритные реле например РЭС-10 с напряжением катушки 12в.