Author: Сергей КИРИЧИК

В силу развития научно-технического прогресса все более актуальными становятся вопросы рационального использования электрической энергии и ведения здорового образа жизни человека в процессе пользования современными техническими средствами. Правильно настроенная освещенность рабочих помещений дает положительный эффект не только в рамках энергосбережения, но и является важным элементом санитарных норм.

Важно, чтобы при достаточной освещенности от внешних (природных) источников света, лампы накаливания не работали на полную мощность. Лампа накаливания должна увеличивать свою световую мощность по мере уменьшения освещения извне. Такой баланс освещенности должен держатся автоматически, в том значении освещенности поверхности рабочего места, которое устанавливается пользователем. Поскольку на рынке современных технологий нет устройств, которые могут совершать функцию автокоррекции освещенности, то создание такого устройства становится важной задачей.

Предлагаю ознакомится с моим прибором предназначенным для измерения и автокоррекции освещенности.

В устройстве реализовано четыре режима работы .

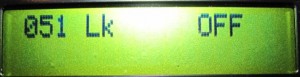

1. При включении прибора отображается текущая освещенность, микроконтроллер не включает при этом лампу накаливания (Режим люксметра).

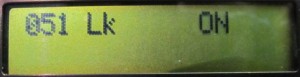

2. При нажатии клавиши «Выбор режима» переходим в следующий режим. Во втором режиме включается лампа накаливания и отображается освещенность при дополнительном освещении.

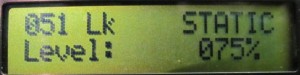

3. Третий режим позволяет изменять мощность работы лампы в процентном значении ее мощности (Диммер). Для этого используются кнопки «+ » и «-». Шаг дискретизации – 5%.

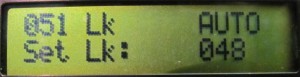

4. В четвертом режиме задаем значение необходимой освещенности в люксах и контроллер обеспечивает стабильный поток света на рабочую поверхность (где находится датчик ) плавно изменяя яркость лампы накаливания. Заданное значение освещенности пользователем может отличаться от автоматически установленного не более чем на 3 лк.

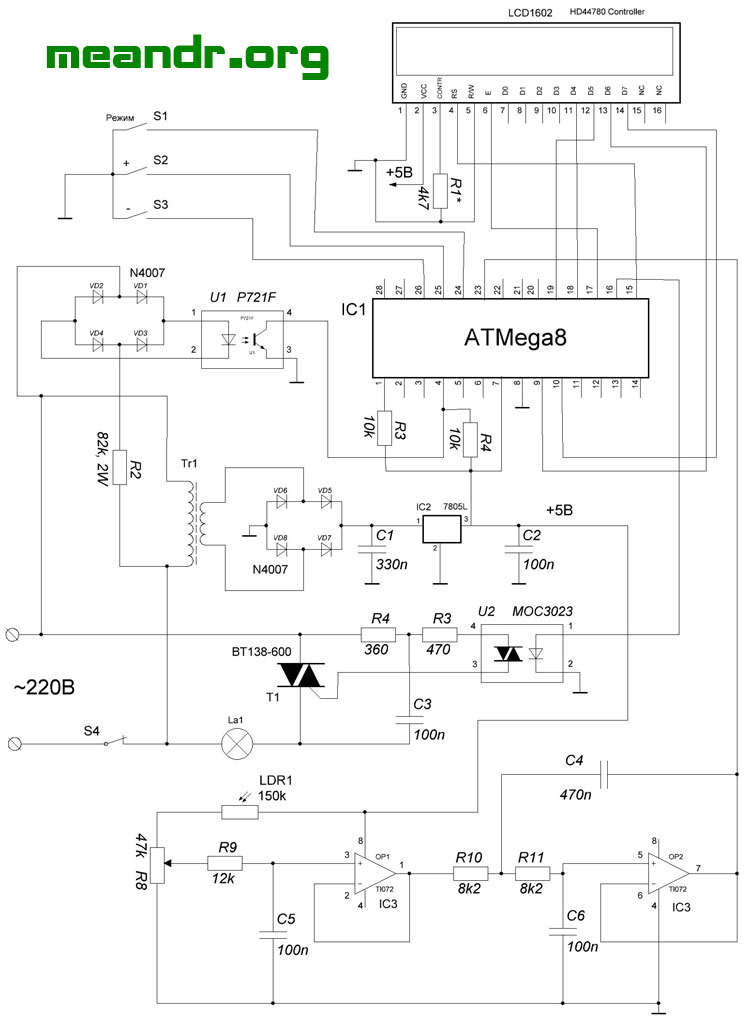

Устройство выполнено по принципиальной схеме изображенной на Рис.1.

Основой данной конструкции является микроконтроллер фирмы Atmel, семейства AVR – ATMega8 (IC1).

Датчиком освещенности служит фоторезистор LDR1, расположенный на крышке корпуса прибора (Рис. 2). Для повышения пределов измерения освещенности фоторезистор закрыт светофильтром. Слабое изменение напряжения в результате освещения на фоторезисторе усиливается интегральным усилителем собранным на специализированной микросхеме IC3 – TL072. Этот сигнал поступает на микроконтроллер через порт РС0.

Градуировка шкалы люксметра проводилась в соответствии с эталонным прибором. При повторении устройства необходимо использовать образцовый люксметр. Резистором R8 устанавливается соответствие в их показаниях.

Для включения лампы накаливания от сети 220 В используется гальваническая развязка собрана на оптосимисторе U2 – МОС3023. Резисторы R10, R11 ограничивают силу тока через оптосимистор. При подаче логической единицы с порта РВ2 прикладывается постоянное напряжение на светодиод оптопары, которая открывает внутренний симистор. Тот в свою очередь открывает симистор T1. С этого же порта поступает сигнал ШИМ, который открывает симистор, срезая части синусоидального напряжения на нагрузке для регулирования мощности работы лампы накаливания.

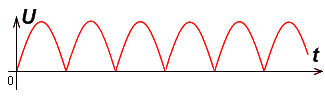

Для правильного построения сигнала ШИМ нужно четко установить частоту бытовой сети. Для этого построен детектор перехода фазы через ноль на графике зависимости напряжения от времени (детектор нуля). Диодный мост на VD5 – VD8 осуществляет двухполупериодное выпрямление (Рис. 3). Такой формы сигнал поступает на транзисторную оптопару U1 – P721F. Транзистор оптопары закрывается только тогда, когда сигнал примыкает нуль на графике. В этот момент микроконтроллер воспринимает логический ноль, который в дальнейшем руководит частотой повторения импульсов ШИМ. Резистор R2 ограничивает напряжение на светодиоде оптопары, его мощность тепловой отдачи должна быть не менее 2Вт.

В схеме использован жидкокристаллического дисплей марки WH1602B-NYG-CT#. Резистором R1 устанавливается контрастность подсветки дисплея. В схему можно включить любой другой дисплей в две строки по шестнадцать значений.

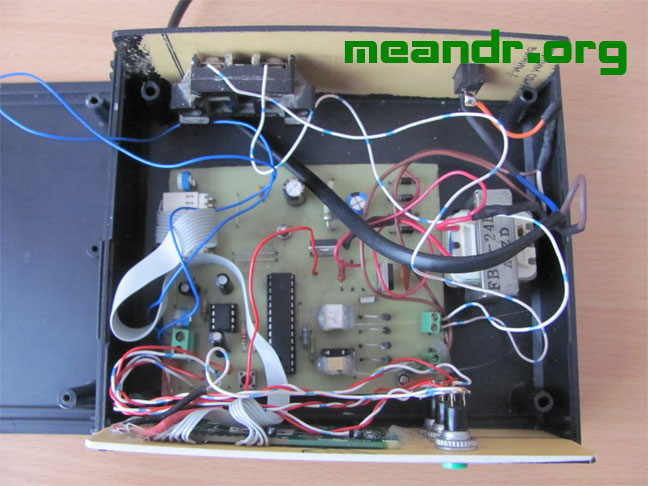

Устройство помещено в корпус с размерами 135х155х55. Фото люксметра с функцией управления освещением показано на Рис.4, Рис.5.

Розетка для включения лампы накаливания находится на задней стенке корпуса прибора.